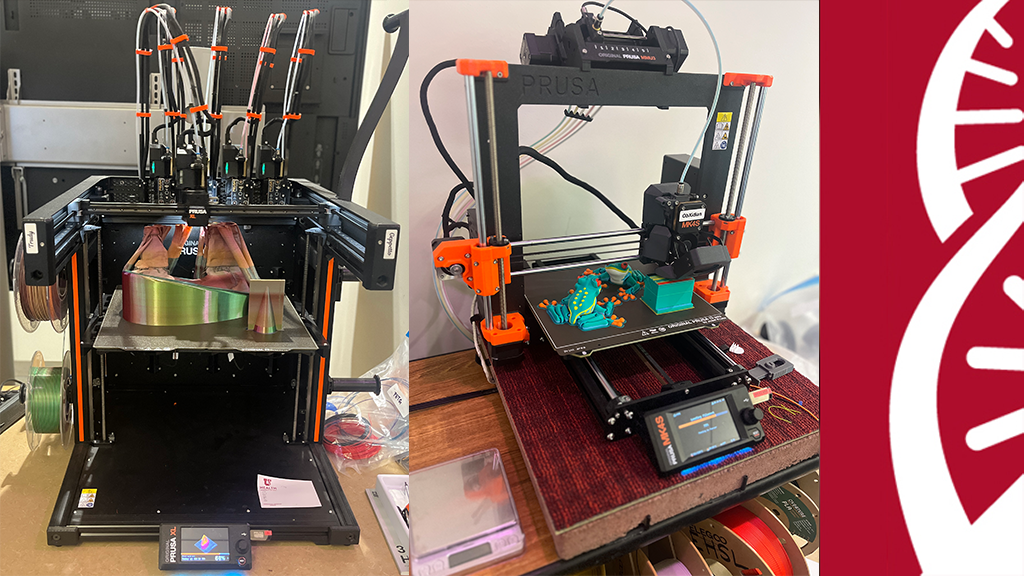

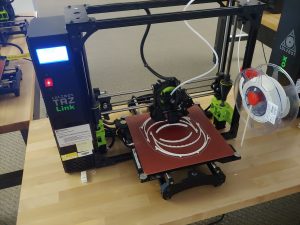

A recent call put out by the Office of the Vice President for Research asking the campus community for donations for Personal Protective Equipment (PPE) inventory had people at the library thinking about what they could do to help. Due to the healthcare emergency caused by the COVID-19 pandemic, hospitals are close to the end of their supply of PPE and healthcare workers run the risk of being exposed to the virus without proper protection. While the libraries don’t have PPE that could be donated like gloves, respirators, safety glasses, face shields, or disposable gowns, they do have access to several dozen 3D printers that could print some of these items.

TJ Ferrill, Head of Creative Spaces at the J. Willard Marriott Library, and Ben Engel, User Experience Developer at the Spencer S. Eccles Health Sciences Library, came together last weekend to begin developing prototypes of these needed supplies. They started with face shields which are used to protect the facial area, including eyes, nose, and mouth, from splashes, sprays, and splatter of body fluids. With the help of a nationwide library and maker community who are working together to prototype diagnostics for face shield production, they came up with a version to share with Tad Morley, University of Utah Health Executive Director of Outreach and Network Development, who is leading the effort for community PPE donations.

TJ and Ben have noted their excitement with the project and are appreciative of library administrators and facilities who offered them access to the 3D printing equipment despite both libraries currently being closed. They are also calling on the support of other 3D printer labs around campus including those located at the Center for Medical Innovation, Lassonde Studios, and College of Engineering to help strategize best practices in producing PPE efficiently. They’ve been working with a wide range of colleagues from throughout campus to make this happen including Mark Howell in Biology, Jon Davies in Engineering, Sabastion Jenson and Scott Bigler of Marriott Library, Kathy Hajeb in Business, and other campus leaders.

While a variety of types of PPE are needed, TJ mentioned that making face shields is currently taking priority because of the immediate need by healthcare workers and the availability of face shield designs for 3D printers. They are expecting to start production after reaching an agreement with University of Utah Health that they meet the medical-grade standards required of PPE. When all 30 3D printers are up and running, they can make up to 300 face shields a day. In the near future, they are planning to make other PPE such as filtered masks.

Video showing several attempts of prototyping the face shields.